Description

First, why go brushless or what advantages will I get from brushless motors. The answer to this question will depend on what you are looking for. A brushless motor setup can be tailored to your goals. However, most people who want upgrades for their blaster are looking for: faster ball or dart speeds, higher feed rates, longer distances, and more accuracy. Brushless motors can achieve all these goals and more.

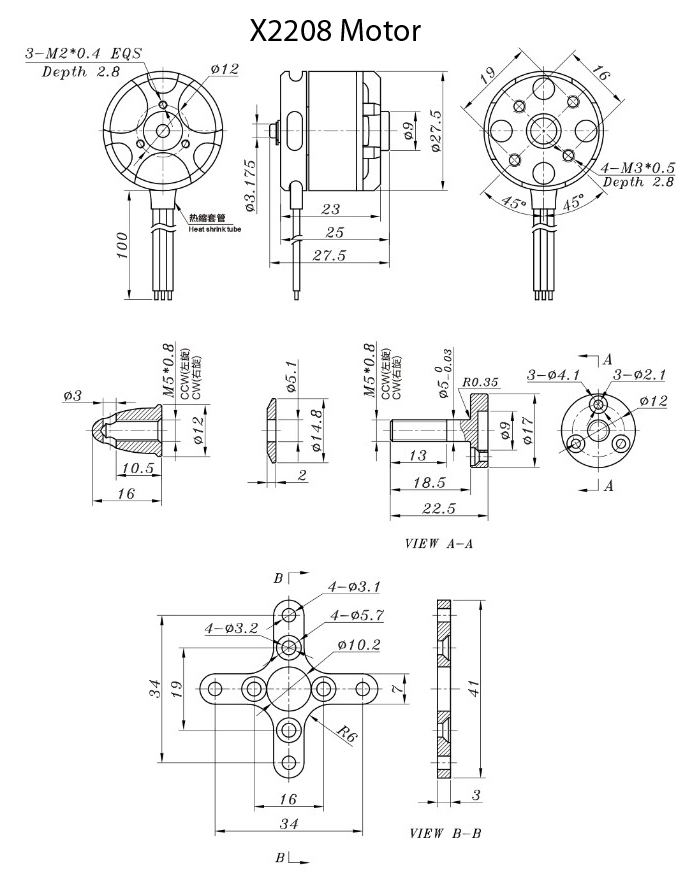

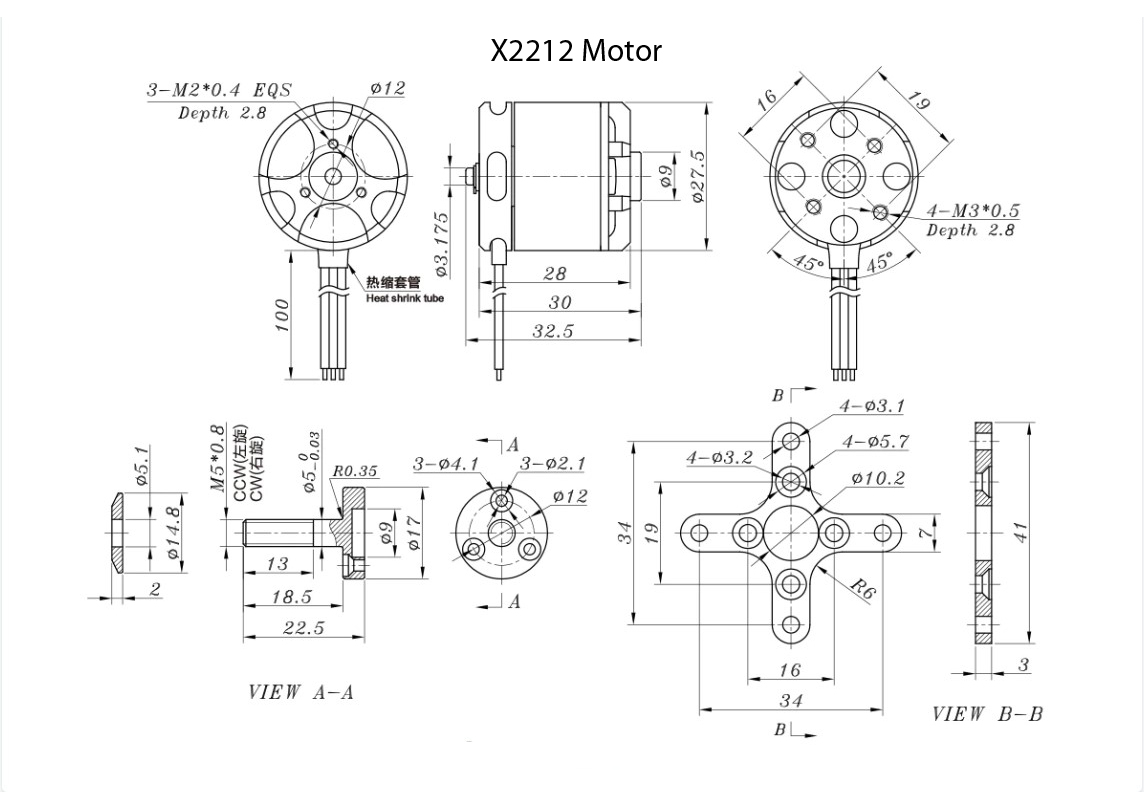

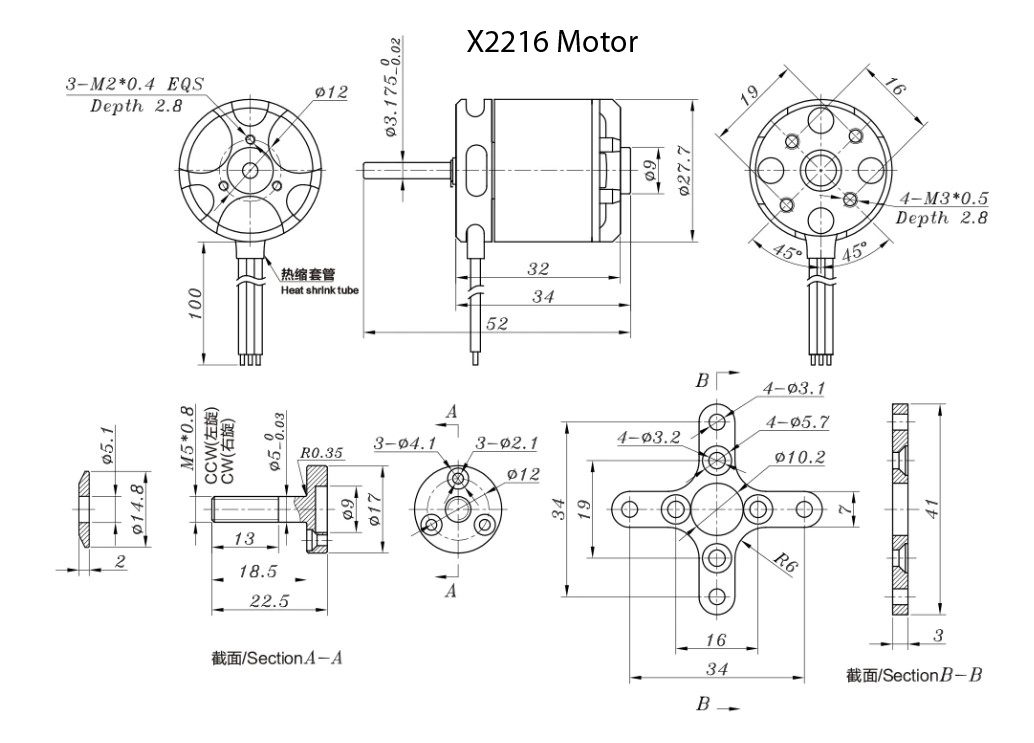

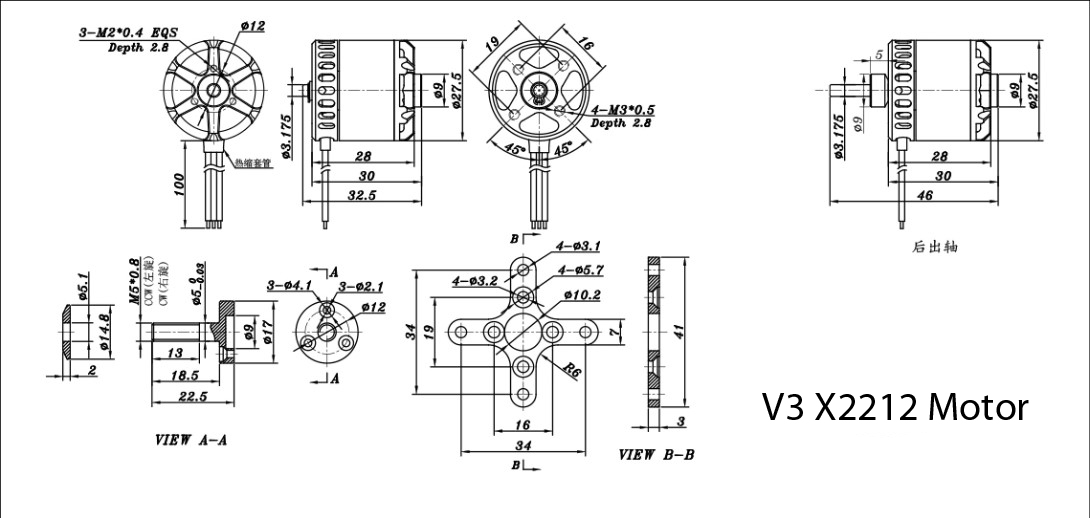

Brushless motors can be daunting in nature, with so many variables like motor size, KV rating, 3s or 4s lipo battery, long shaft, short shaft, left-handed thread vs right-handed thread and so on. Someone just getting into the hobby might want to just give up. But it is not that hard once you get used to the terminology and components.

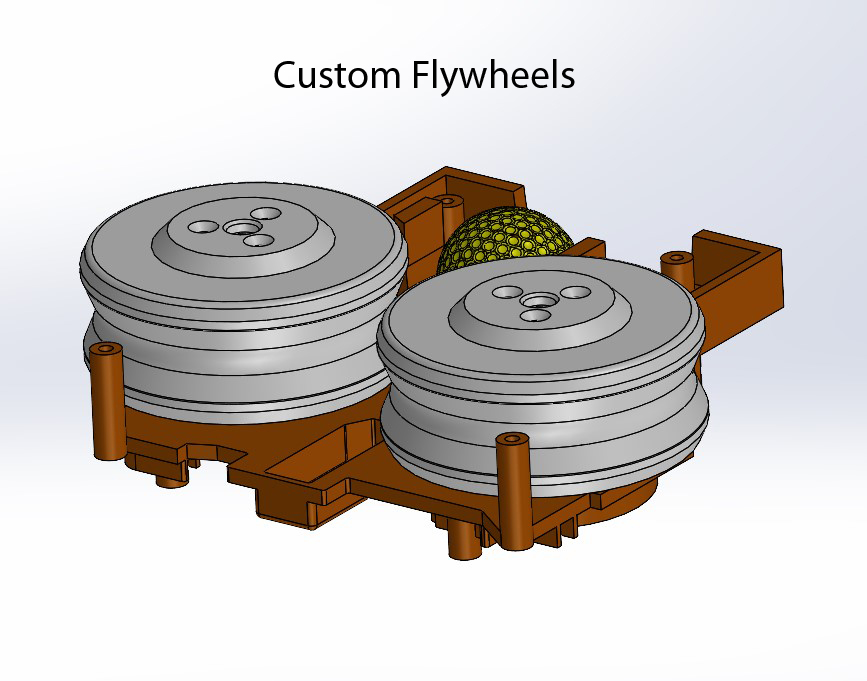

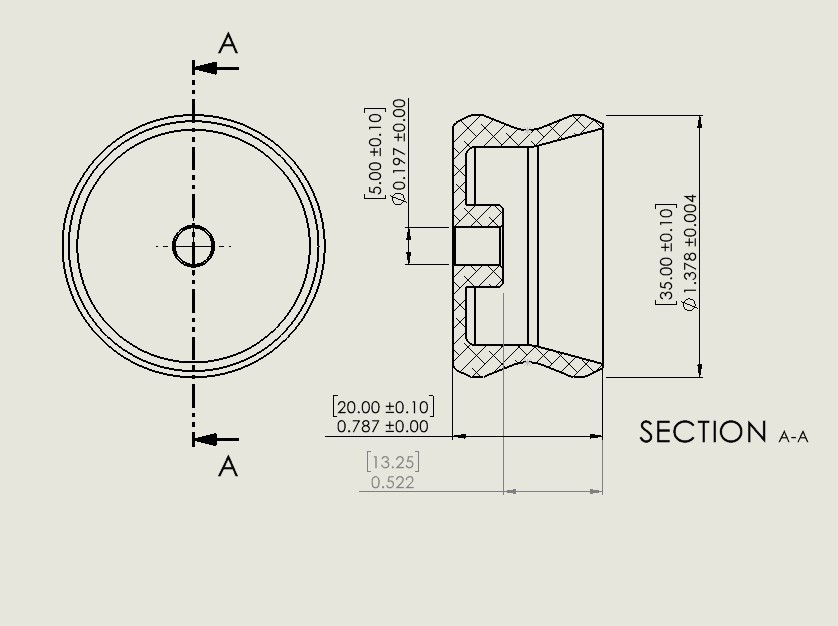

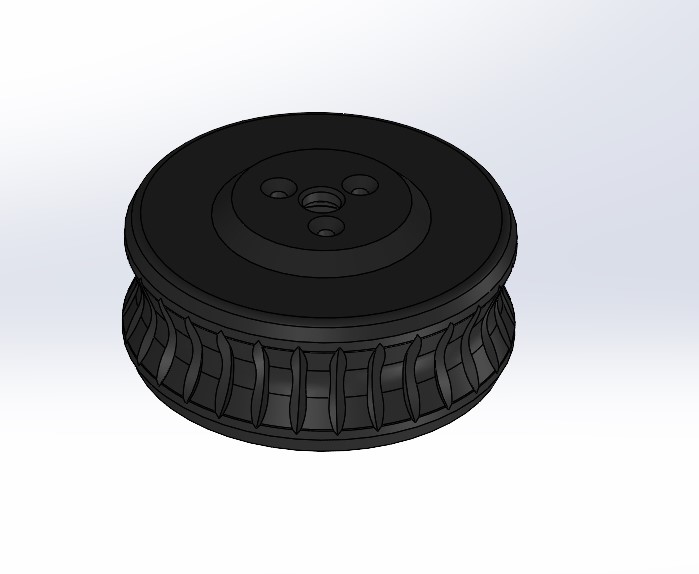

So here is what we did to make it easier for you. We have spent countless hours testing and evaluating over 100 brushless motors under conditions specifically designed for a blaster. Although the motor is just one part of the application, you must start somewhere. So, we included conditions like small vs large diameter flywheels, small motors vs large motors, 11.1 volts (3s lipo) vs 14.8 volts (4s Lipo), medium KV rating vs high KV rating, metal vs composite flywheels, flywheel spacing or “crush” as some call it, among other things. And on our test bench we ran test after test with different variables to see what works and what doesn’t. We documented motor rpm and projectile speed and came up with our own efficiency test to rate each motor/flywheel/battery setup. We used these results to come up with recommended setups, something most other vendors won’t give you.

Although there is too much to explain here regarding our testing, we will lay out the advantages and reasons why we chose these motors over others for this application.

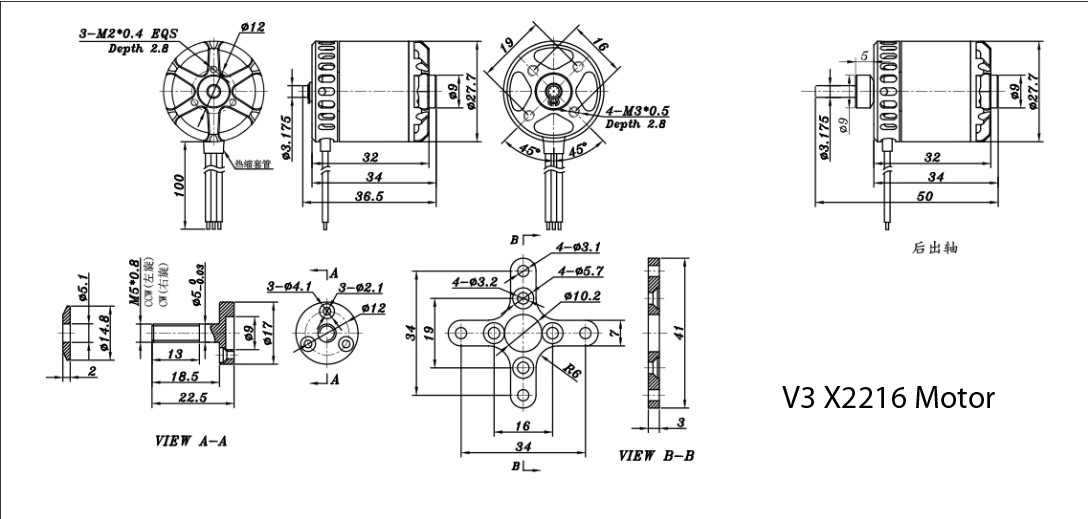

#1 High Quality – The motors are CNC machined from 6061-T6 aircraft grade aluminum to high tolerances. The solid shaft is made from 420 stainless steel and heat treated to improve its strength and resistance to bending/breaking. High quality NMB (Japanese) bearings are used for long life and stable operation. The motors windings are hand wound and make for a tighter, neater coil, which helps keep the size of the motor as small as possible. V3 motors are dynamically balanced for lower vibrations.

#2 Motor Size – These motors are comparatively long in size when compared to most other “drone” like motors. The longer motors help in two ways, the first is the distance between the bearings is longer, giving more axial support when a projectile is pushed through the flywheels. You don’t see the motor shaft bending during high crush applications. Secondly, the longer motors have longer magnets and longer windings which makes more power, when compared to shorter “drone” like motors.

#3 Mounting – These motors also allow the flywheel to be mounted directly to the motor housing and not via a shaft like most drone motors. This is a great advantage over the shaft mounted motors and prevents flywheel slippage or the flywheel coming loose on a motor shaft, which is a common problem in this application. The other benefit is that the contact area of the flywheel to the motor housing is considerably higher than that one with a shaft mount and the mass of the flywheel is concentrated over the motor housing and not extended like a drone motor. Both features reduce vibration in the motor/flywheel combination and allow more power to be applied to the flywheel.

#4 Power – The KV range on these motors is suited for this application and can produce power using a suited flywheel that can propel projectiles above 200fps. In addition, these motors are rated for 3s or 4s lipo batteries giving you a range of power to choose from.

Reviews

There are no reviews yet.