Mar

29

Mar

29

3DPS Filament Extrusion

- March 29, 2021

- 1 Comment(s)

Over the past five years, we’ve purchased a countless number of filament spools for our 3D printers. We’ve tried numerous different brands and types of materials, only to come to one conclusion; We should have control over our filament. While there are many factors involved in producing our own materials, the positives outweigh the cost. Poor quality materials from outside vendors caused hours, even days, of manufacturing delay. Without a good quality material, nozzles would jam; colors would come out skewed or dull; certain settings needed to be adjusted. Sourcing our own materials allows us to make custom colors, different filament sizes (1.75mm and 2.85mm), and modify the material properties by adding polymer modifiers.

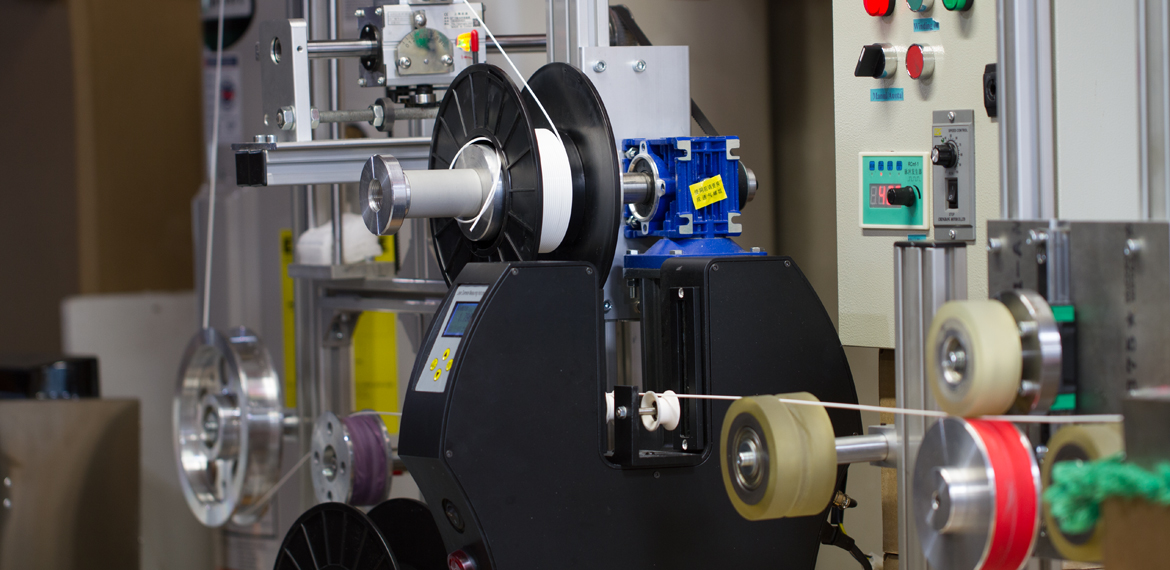

Filament extrusion was an incredibly complicated endeavor for us to take on, but through trial and error we’ve learned how to achieve a high quality product. We start off with high quality resins from a top-rated American PLA manufacturer. Thanks to the customizability that 3D printers allow, we’ve also fine-tuned our extrusion process with custom made tooling of our own design. Our USA-made masterbatch colorants are made particularly to 3D Printed Solid hue specifications. We have a number of color-matching filaments which are meant to match products, allowing all the enthusiasts to seamlessly blend custom parts with their projects. We use Lost-of-Weight moisture analysis equipment in combination with desiccant dryers to monitor the resin’s moisture level prior to extrusion. Using very fine filtration screens, our extruder filters out even the smallest of particle contaminants. During the extrusion process, we monitor the filament’s size with a laser micrometer and No-Go gauges to be consistently a high-standard compliant product. We also have the capability to run different spool sizes for larger prints; just ask about bulk filament spools!

Months and months of testing and experimenting has led us to our very own personalized 3D Printed Solid filament extrusion line! Contact us at 3dps@3dprintedsolid.com in order to find out more about purchasing 3DPS filament.

One comment on “3DPS Filament Extrusion”

I’m a soon to retire software developer endeavoring into the world of 3D priming as a hobby to keep me engaged after retirement. It’s been about 8 months now and I have acquired 3 Bambu Lab printers: a P1S, an A1 and N A1-mini. Lately, lasers have been piquing my interest and I’ve started preparing my wife for the purchase :).

It’s exciting to find a local company that aligns with my interest!