Mar

19

Mar

19

3D Printing

- March 19, 2021

- 0 Comment(s)

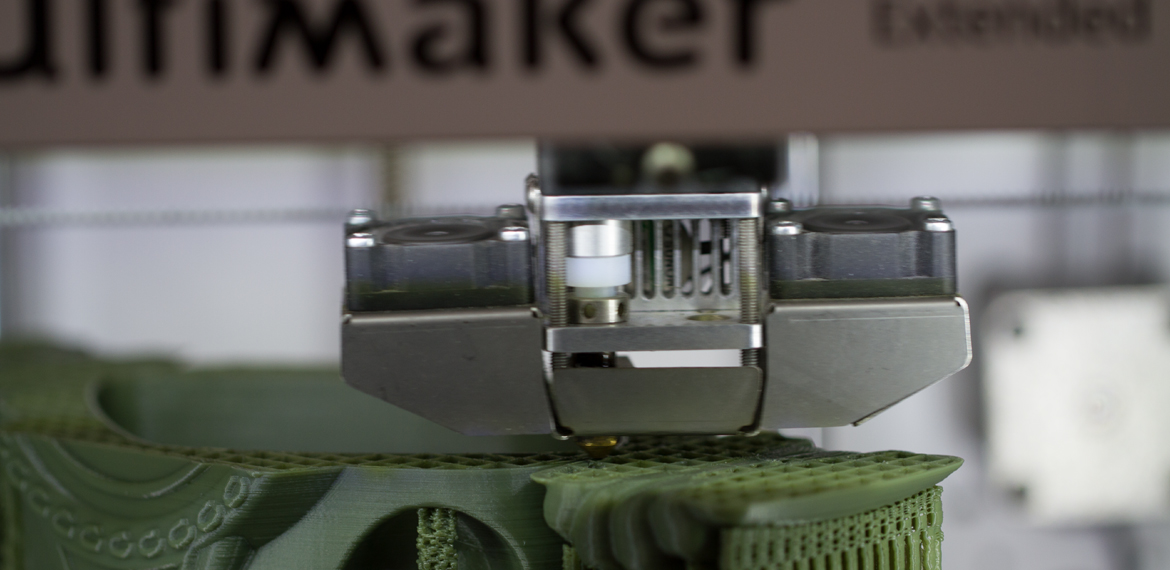

From 3D printed houses to 3D printed pizza, the 3D printing field has been rapidly expanding over the past decade. Colleges are offering degrees, hobbyists are starting their own 3D printing businesses, and more companies are upgrading to this newer, more cost effective manufacturing method. 3D printing has a fairly simple concept: a 3D printer extracts material through a nozzle, following digital print to create layer after layer until the desired product is formed. However the actual process of loading, running, and maintaining a 3D printer isn’t as simple as it sounds. It’s kind of like when someone knocks on your door, selling something that seems just too good to be true. You know, it’s only $29.99 a month for the first 12 months, but they don’t tell you about the 100-200% price increase after the first year. We’ve ALL gotten that surprise before. We’re going to take a look at a couple “myths” that have been surrounding the 3D printing community for a little while now.

YAY, MY FIRST 3D PRINTER! I CAN PRINT ANYTHING, RIGHT?

The answer is a little more complicated than just a simple yes. Yes, If you have a plethora of experience with CAD (Computer Aided Design,) slicing, and a decent amount of mechanical and technological skill. Don’t get me wrong, I’m not trying to scare you! Every process of 3D printing is learnable; but it is definitely not to be underestimated. It’ll take a good bit of research as a newbie to get your printer up and running, but it’ll be worth it when you do!

With the industry booming, there are beginner-friendly websites popping up everywhere with millions of .STL files for anyone to download and start printing. Some of the more popular sites used are Thingiverse, MyMiniFactory, and GrabCAD Library. If that’s just too easy and you’re ready to start diving into creating your own .STL files, there are numerous beginner-friendly CAD softwares that will build your 3D printing knowledge with just a little bit of time and effort.

OFF ON A TANGENT: My previous job was working in a polymer lab in a large wire and cable facility in Lancaster County, Pennsylvania. I bounced around positions over the years, from Extrusion Operator to Process Technician to Toolroom Supervisor, finally settling with Project Engineer for the Data Communication Competence Center. We had our own prototype extrusion line and many pieces of expensive, fancy equipment to measure the polymer’s characteristics. Instead of running the machines, my job was running the CAD and simulation portion of the lab. I would input CAD models and polymer data into a simulation software to analyze the flow characteristics and degradation areas. I then would modify the extruder designs to maximize productivity, effectiveness, and quality. Sounds boring, right? But after 27 years of loyalty, my patience with management’s superior selfish attitude was at an all-time-low. So I made a rough and life-changing decision; In 2015, I leaped into 3D printing and created 3D Printed Solid so I could make my own rules, ensure my business ran properly, and keep customer satisfaction as a top priority. 3DPS is approaching its six year anniversary in a couple months and I wish I would have made the leap sooner.

I FOUND MY 3D MODEL! PRESS A BUTTON & THE REST IS THE PRINTERS JOB, RIGHT?

Wouldn’t it be nice if it was always that simple? Just like the question above, yes is too simple of an answer. Every 3D printer brand is going to have it’s own way of working; through extension, that means every printer is going to run optimally at different settings – that you’re going to have to figure out. I can’t tell you how many times I’ve shocked people when they ask how long a part takes to produce. It takes time and experimentation to get a printer to produce a structurally sound, cosmetically appealing 3D print. Finding the perfect balance between quality and manufacturing time can be tricky; but keep in mind, your efficiency increases with each printer you buy!

It might be an intimidating adventure, but 3D printing is expanding to new heights every day. Go ahead, spend some time doing research, bite the bullet and buy that 3D printer and get ready to create unique products.